It’s no secret that sustainability is top of mind for companies across nearly every industry. In fact, a recent study found that 65% of companies rank sustainability as one of the most important issues to address in their short and mid-term planning. While the direct impact of a more eco-friendly business model is helping to protect the environment, there are a number of other benefits for companies in focusing on more sustainable practices.

It’s no secret that sustainability is top of mind for companies across nearly every industry. In fact, a recent study found that 65% of companies rank sustainability as one of the most important issues to address in their short and mid-term planning. While the direct impact of a more eco-friendly business model is helping to protect the environment, there are a number of other benefits for companies in focusing on more sustainable practices.

For example, thinking more critically about how you’re using natural resources can help reduce waste and unlock more efficient workflows. This is especially true for companies that rely on large quantities of print pieces as a core component of their marketing, sales, or operations strategies.

Working with a strategic print partner that leverages a digital print automation infrastructure can help reduce waste, incorporate more eco-friendly ink and paper, and increase the efficiency of your print workflows, all in service of a more sustainable approach to print.

Here, we’ll look at how print automation can help increase the sustainability of your commercial print, and how a more mindful, efficient process can help produce more effective, higher-quality print collateral.

Print automation allows you to print precise quantities in a more timely, strategic manner

Successful commercial print programs require the ability to print large quantities of time-sensitive communications in a relatively short amount of time. For example, documents like invoices and account statements are printed on a recurring basis, and these jobs need to be completed quickly to provide accurate information to customers.

Printing these types of documents on a more traditional offset press requires creating large print quantities to achieve economies of scale and experience a return on investment. However, this often results in large numbers of excess copies that companies have to store, some of which may not be used. This can create a large amount of waste, both in terms of paper and ink, but also in terms of the resources required to ship your copies to you and money spent on warehousing.

A print automation infrastructure that leverages on-demand print technology can accelerate the process of printing the precise number of copies needed precisely when you need them. This virtually eliminates the chance of printing excess, unused copies. Plus, the ability to edit design files in real time makes it possible to update campaign components like messaging, promotions, and product information to avoid printing inaccurate pieces that you can’t use.

What’s more, a print automation system can integrate with your customer relationship management (CRM) or enterprise resource planning platform (ERP) to provide on-demand print capability that is triggered by any number of events or customer actions to create more timely print the moment it’s needed.

Integrating your CRM with a print automation system also helps increase the sustainability of your commercial print needs by using a data-driven approach to create custom, highly-personalized print pieces that are designed to get results.

Variable data printing (VDP) allows you to use a variety of customer insights to create commercial print that connects on a deeper level with your target audience in a way that prompts them to take action without the need for subsequent campaigns that require additional resources. For example, we partnered with a luxury Las Vegas casino to print personalized, relevant direct mail offers that increased response rates while optimizing their use of resources.

A print automation system makes it possible to use innovative, eco-friendly materials via digital print technology

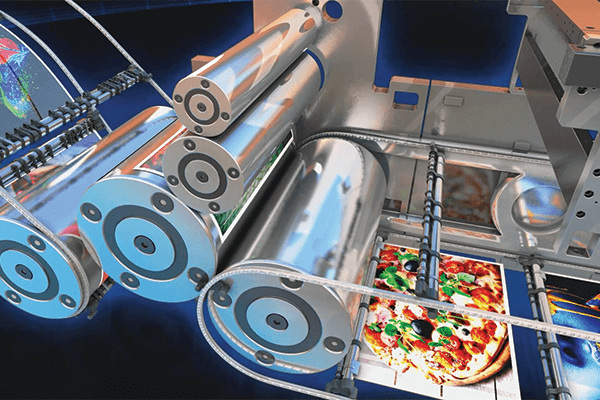

Print automation systems that harness the power of digital presses can print high-quality pieces faster and more efficiently, and they can also allow for the use of more sustainable inks and substrates to help reduce your carbon footprint without sacrificing print quality.

For example, digital inkjet presses apply ink via small printheads as opposed to using large, pre-produced plates that are common with more conventional presses. This application method is faster, more efficient, and creates the same color quality and stability. Plus, the continued development in ink technology has introduced inks that require less water and colorants to produce high-caliber pieces.

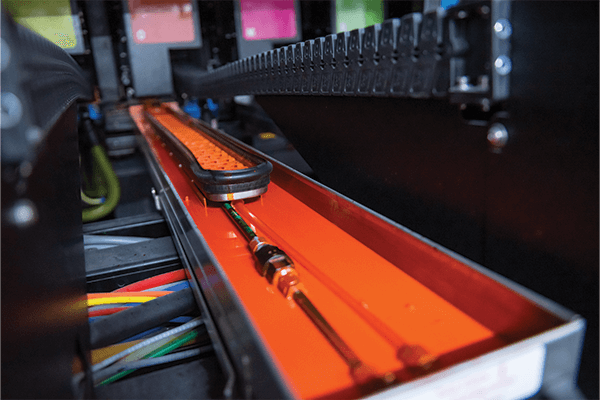

NanoInk® technology uses pigment particles that have significantly smaller diameters than other inks, which makes it possible to produce stunning images with less pigment. NanoInk technology also allows for colorants to be shipped as concentrates and mixed with water onsite. This means NanoInk can be shipped without water, which reduces space and weight during shipping to help you cut your carbon footprint.

Make your print even more eco-friendly by choosing recycled substrates, or those produced with some percentage of post-consumer fibers. The challenge with using recycled substrates though is that some offset and even digital presses cannot print full-color on recycled sheets without running the risk of bleed.

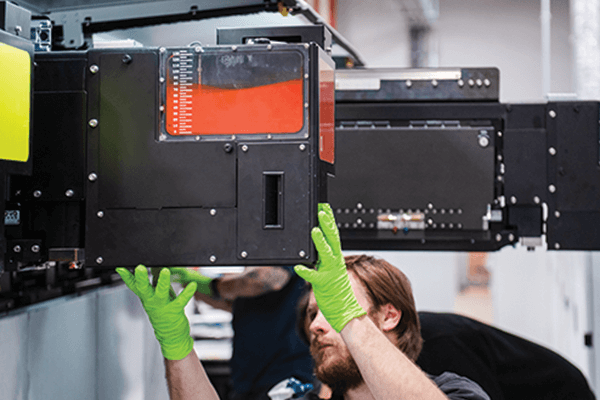

This is where Nanographic Printing gives you the ability to print on any off-the-shelf-recycled substrate, regardless of the amount of post-consumer fibers or whether the sheet is coated, uncoated, treated, or untreated. The capability to print on any off-the-shelf recycled substrate not only makes your commercial print more sustainable, but it also helps you avoid product availability issues or breakdowns in the paper supply chain.

In fact, this combination of flexibility and a more sustainable approach to print is a large part of why we choose Landa’s nanographic printing technology to help usher in the future of commercial print.

With a long history as a strategic print partner, our automated print solutions can help you increase the sustainability of your commercial print while also optimizing your print communications in order to get results. Learn more about how Quantum’s experience and knowledge in print marketing automation and software integration can help you unlock more sustainable — and efficient — commercial print.