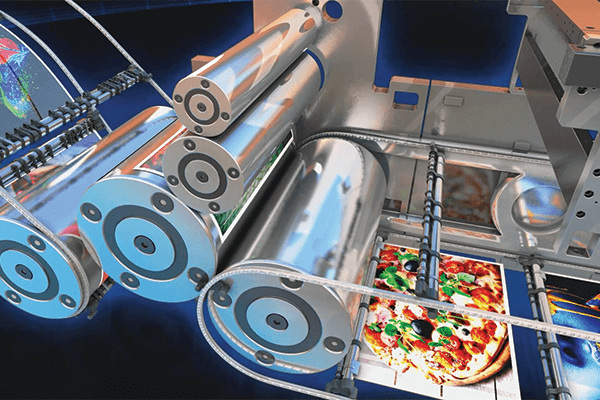

The choice between offset vs. digital print is one that marketers have to weigh when deciding the right print technology for producing print collateral. Depending on the job, factors like print run, cost, production time, and quality usually tip the scale into the offset or digital camp, but the introduction and development of Nanographic Printing® can help marketers experience the benefits of digital print technology with the added value proposition of achieving even more efficient economies of scale.

The choice between offset vs. digital print is one that marketers have to weigh when deciding the right print technology for producing print collateral. Depending on the job, factors like print run, cost, production time, and quality usually tip the scale into the offset or digital camp, but the introduction and development of Nanographic Printing® can help marketers experience the benefits of digital print technology with the added value proposition of achieving even more efficient economies of scale.

With nanographic printing, marketers can combine the full-color quality of offset with the speed and productivity of digital to create print marketing collateral that maximizes the investment in print. Here, we’ll look at a couple of key ways in which nanographic printing can help marketers create more cost-effective print communications.

Nanographic printing offers increased efficiency and speed

Traditional offset printing comes with a variety of pre-production processes due to the custom metal plates that are required for each job. Not only does the fabrication of these plates increase cost and lead time, they also make it difficult for marketers to quickly pivot from one project to another. While digital print technology eliminated this hurdle by automating workflows and eliminating lengthy set-up times, nanographic print takes speed and efficiency one step further.

For example, nanographic printing platforms leverage digital flexibility via instant job turnovers and the ability to print from multiple data streams without production downtime. Nanographic printing also makes it possible for marketers to print variable data and collated signatures on an as-needed basis via on-demand print technology.

Landa’s nanographic presses can also help marketers outpace the competition in terms of print speed. The Landa S11P Nanographic Printing® Press — which Quantum just added to its digital print fleet — can print up to 11,200 sheets per hour. What’s more, the S11P can achieve this print speed on any off-the-shelf substrate without any pretreatment. This enhanced level of print efficiency delivers high-quality print collateral quickly to help marketers meet project deadlines.

Nanographic printing provides superior print run flexibility

Choosing offset printing comes with a couple of inherent complications, particularly the economies of scale necessary for marketers to see a return on their investment. Offset requires marketers to print large quantities in order to maximize their print marketing spend, but such large quantities often result in waste, either from throwing out unused copies or from the added costs of warehousing excess pieces.

Nanographic printing makes it possible for marketers to produce print runs of any size at any time, be it small or large, without worrying about compromising quality. For example, run-to-run variances can become an issue on some digital presses, especially with small print runs or those produced via on-demand print technology.

The unmatched quality and precision of nanographic printing makes print variances a thing of the past, and the ability to produce any print quantity in an on-demand fashion or in as many runs as necessary to meet demand helps marketers unlock more advantageous economies of scale. Additionally, the ability to print any quantity at any time makes it cost-effective for marketers to conduct A/B testing on the kind of messaging or visuals that best engage their target audience.

Nanographic printing helps reduce waste

Marketers are constantly tasked with ways to increase efficiency and reduce waste. Some of the biggest sources of waste with print collateral come from choosing an offset press and the large quantities that come with this kind of print. Unused copies are either thrown out or warehoused, and the latter increases the total cost of ownership.

The digital, on-demand nature of nanographic printing can help marketers virtually eliminate warehousing costs, and the ability to more efficiently manage print runs helps marketers more effectively use the resources — paper, ink, and water — that are part of producing print marketing materials.

What’s more, the capability to produce precise quantities can help marketers streamline the necessary packaging and shipping processes to receive jobs from the printer. Printing the exact run you need can also play a small part in reducing your carbon footprint by shipping the precise number of copies you need to meet demand.

Quantum’s investment in nanographic printing technology via our Landa S10P and S11P presses presents a variety of unique, exciting possibilities for personalized, print-on-demand mailing and fulfillment services that can help you unlock more profitable economies of scale.

The new S11P also helps us create stunning color quality and range on any off-the-shelf substrate — coated or uncoated, film or plastic — with no pretreatment required to print any project in a quick, cost-effective, and sustainable manner.

Learn more about our commercial print services and how our use of nanographic printing can help you take your print projects to the next level.